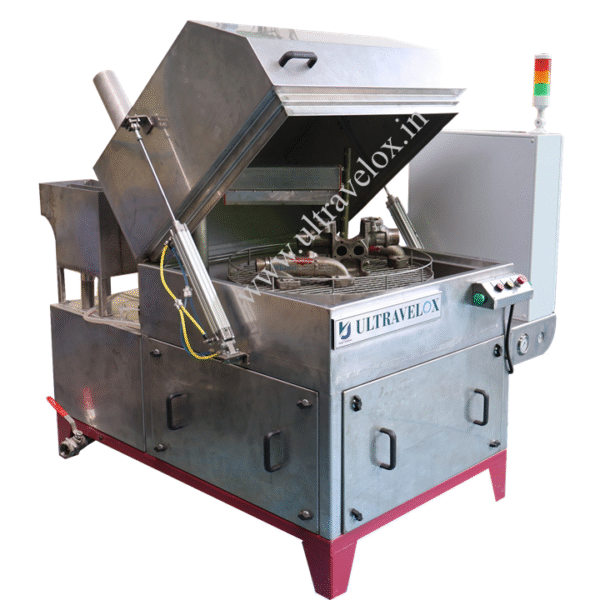

TOP LOADING ROTARY COMPONENT CLEANING MACHINE

The Rotary Component Washing Machine Uses only hot water and biodegradable Alkaline detergent products – making them good for the environment and good for the operator. Our Rotary Table Component Cleaning Machine designed for fast, effective space saving and economical – high levels of cleanliness can be achieved for low cost and little effort.

The development of ULTRAVELOX Rotary table washing machines has made it possible to clean manufactured components quickly and efficiently. It is suitable for parts with basic geometry that have a batch of small parts loaded on a basket or individual big parts on fixtures. The Rotary table sizes are available from 600mm to 1800mm Diameter.

In Rotary Table Spray Washers Components would be loaded on Rotary basket, which is rotated by a motor and gearbox arrangement in slow speed.

During the rotation, the solution (water along with alkaline) from the tank is pumped with the help of High Pressure pump to wash chamber of Top Loading spray washer through inline filter multiple and 3D spray nozzles located above, below, and to the sides of the rotary table to attain higher degree of cleaning results. From Rotary Table Washer Wash chamber it drains back to the tank via a basket filter. Spray pressure indicator (Glycerine filled pressure gauge) is provided to monitor the line pressure. Low water level indication and Digital temperature indicator cum controller is provided on the control panel.

- Complete SS304 Construction

- Automatic Pneumatic Door opening & Closing or Gas Spring for Manual Operation.

- Well-designed Rotary table washing machines Wash Chamber with Mechanical Door Seal ~ No rubber seals to replace or leak!

- High pressure vertical / horizontal pumps.

- High pressure centrifugal blower with Electric hot heater for component drying.

- Slow speed Basket Rotation.

- Low Water Shut-Off ~ Protect your heat elements from low water conditions

- Stainless Steel V-Jet Nozzles ~ Durability and precise 360 degree cleaning coverage

- Rotary Table Component Cleaning Machine is provided with PLC Controlled Industrial Control Panel

- Gravity Filter to keeps tanks free of larger debris

- Mist collector for Exhaust systems.

- Rotary type component cleaning machines wash tank can be also provided with Oil separator / oil Skimmer for effective removal of oil from the tank in high volume.

- Washable Filtration system for reuse of aqueous solution.

- A thermostat-controlled electric immersion heater in Rotary Basket Cleaning Machine maintains the aqueous cleaning solution at the desired temperature.

- Two tank concepts for offline filter concept can also be provided in Rotary Table Component Cleaning Machine for high Millipore value requirement.

- Our Machine performance, Reliability & quality superior than component cleaning machine manufacturers.

- Filtration range of 150 micron to 5 micron filtration can be provided with online & offline filtration.

- Customized Air Knife for drying.

- Two hand push button for cycle Start.

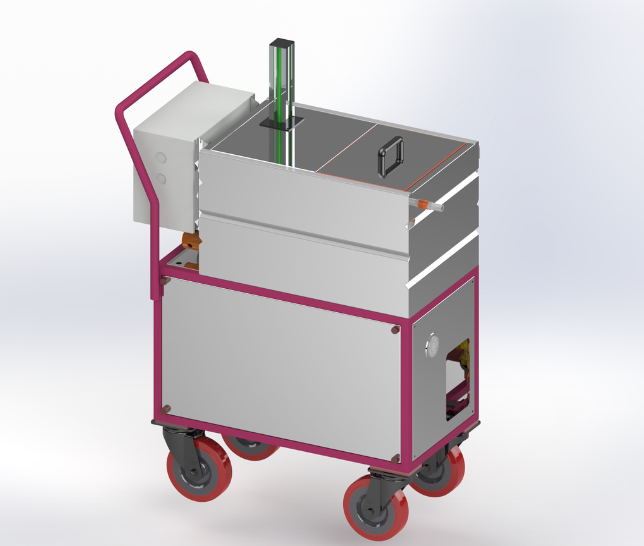

Our technical experts and design team can customize the Rotary table type component cleaning machine for enhanced quality clean benefits, handling, and productivity. The design of custom systems is possible with a Rotary table that is as large as needed and with weight capacities that match.

- Dynamic range of basket sizes – 600mm, 720mm, 1000mm, 1500mm & 1800mm diameter.

- Process Pressure wash / Rinse / Drying

- PLC & HMI Controlled Panel.

- Wash solution temp varies from 50 to 65 degree

- Loading Height @ 950mm

- Tank Heater 9Kw / Blower 5 HP

- General spray Pump pressure from 3 to 25 bar according component cleanliness level requirement. On request can supply up to 150 bar.

- Single Tank capacity from 110 litres to 400 litres.

- Mist collector

- Oil separator

- Duplex Filtration system

- Two tank Filtration

- Paper band filtration

- Magnetic separator

- Automatic door opening

- Suitable for general cleaning of different components cleaning in the same machine. Supports cleaning of wide variety of components.

- Intermediate or final cleaning in the automatic parts washer.

- This Rotary cleaning machine can be designed to get Millipore level by suitable fixturing & Pump selection.

- General Engineering washing by Rotary Table Type Component Cleaning Machines

- OEM’s

- Aerospace

- Manufacturing

- Railway Degreasing.

- Automobile component washing machine

- Hydraulics industry – Cylinder washing machine.

- Metal Pressing Industry – pressed component washing machine

- Metal Casting Industry

- Printing Industry.

- Crankshaft Washing Machine.