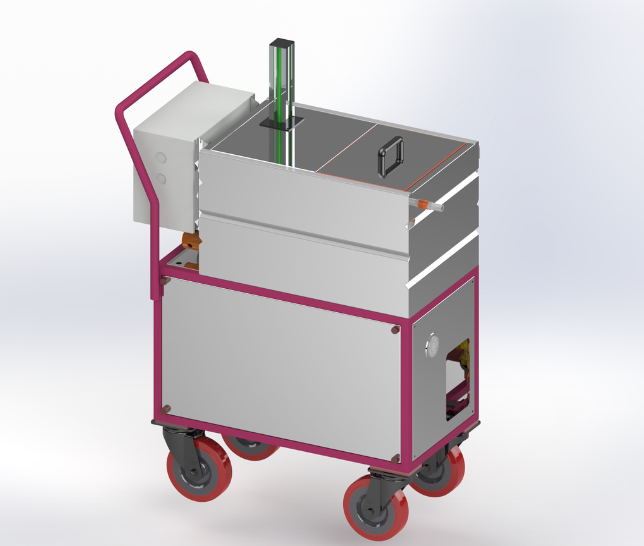

Small Components Cleaning Machine

Ultravelox’s small component cleaning machine, “THUNDER”, is a specialized solution within our range of Industrial Parts Washing Systems designed to clean and dry small machined components perfectly, without damaging the surface or geometry of the product. Our Thunder parts washer uses a unique cleaning process that combines spray and immersed washing, performing parts washing in continuous rotation along a horizontal axis. The slow rotation of the basket ensures that even shadowed regions, which are inaccessible by direct spray, are thoroughly cleaned. This machine features an innovative oil separator, effectively removing oil and contaminants from the fluid during recycling. Thunder is ideal for fittings, fasteners, delicate small parts, and CNC-machined components, and is widely trusted by our customers. It excels at cleaning and drying small parts that are challenging to process in vertical rotating basket machines, making it perfect for tiny components like stampings, bearings, rivets, CNC-machined small parts, and screw machine items.

- Batch type for Small parts washing & Drying in single chamber.

- High cleanliness level achieved due to rotation, immersion & spray action.

- Easy loading & unloading.

- Less power consumption due to unique machine design.

- Less floor space.

- Blind holes & shadow region also can be cleaned.

- In build Oil Separator.

- Loading Capacity from 10 Kg to 40 Kg.

- Baskets mesh size available according to Component requirement.

- Pump Pressure 4 Bar to 16 Bar.

- 200 Litre tank capacity.

- Machine Size 1800mm x 1350mm x 1330mm.

- Filter : 150 Micron.

- Weight 300 Kg.

- Mist collector.

- Oil separator.

- Duplex Filtration system.

- Two tank Filtration.

- Paper band filtration.

- Magnetic separator.

- Automatic door opening.

- Small press parts.

- Small CNC machined parts.

- Nipples, Fasteners, Washer…

- Brass Fittings, SS Fittings…

- Stamped Components.