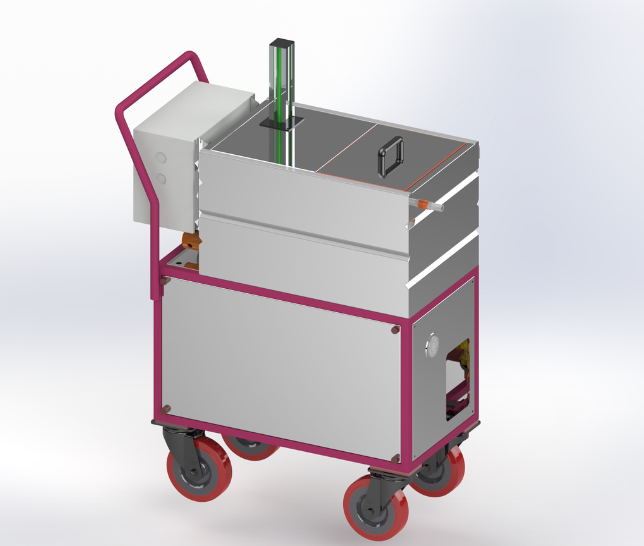

Customized Part Washers

UltraVelox designs and manufactures Customized Part Washers to meet specific cleaning challenges across diverse industries. Whether it’s delicate precision parts or large, heavy-duty components, our systems are engineered to ensure thorough, efficient, and safe cleaning.

- Fully Tailored Design: Built specifically for the shape, size, material, and contamination level of your components.

- Versatile Cleaning Methods: Can integrate spray jets, immersion baths, ultrasonic cleaning, or combination systems.

- Material-Compatible Construction: Built using SS304/SS316 or other materials suited to the cleaning media and parts.

- Flexible Chamber Sizes: Custom-built to accommodate single parts or batch processing.

- Energy-Efficient Systems: Optimized water and power usage with heat recovery options.

- User-Centric Control: PLC-based interface with recipe storage for different components.

- Low Maintenance: Modular design for easy access, cleaning, and serviceability.

- Auto Loading & Unloading option Available

Parameter | Specification (Customizable) |

Chamber Dimensions | As per component requirements |

Material of Construction | SS304 |

Cleaning Method | Spray, immersion, ultrasonic, vapor |

Tank Capacity | 100 to 1000 liters or as required |

Heating System | Electrical |

Temperature Range | Up to 70°C |

Control Panel | PLC with HMI / Manual |

- Mist collector.

- Oil separator.

- Duplex Filtration system.

- Two tank Filtration.

- Paper band filtration.

- Magnetic separator.

- Both side Loading & Unloading option.

- Transmission component washing

- Diesel Engine Degreaser

- Large Parts industrial degreaser

- Military Applications Degreaser

- Aircraft Wheel Parts Washer degreaser.

- Aircraft Brake Parts cleaner machine

- Aircraft Bearing Parts Washer

- Diesel Engine component washing machine

- Electric Motor Parts Washer

- Rail Bearing Parts Washer

- Locomotive Crankcase Washer

- Machined casting cleaning machine.

- Steel Mill Bearing Parts cleaner machine

- Wind Turbine Gearbox Parts Washer