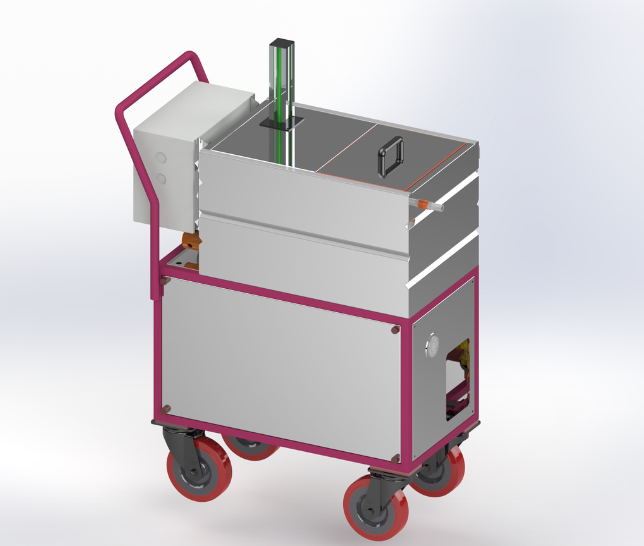

Cabinet type cleaning machine

Ultravelox Cabinet component cleaning machine are designed for immersion washing with aqueous detergents. In this type of industrial component cleaning machine multiprocessing can be done in single chamber without component transfer mechanism and process like High pressure alkaline Washing, Ultrasonic, Rinsing, Compressed air blow, Hot air blow and Vacuum drying facilities can be done.

These washing systems may be single-stage and multistage completely customisable according to the treatment requirements of the parts to be cleaned. These machines base their operation on the rotation of the basket around its horizontal axis and are suitable for washing Components of complex geometry pose great difficulties in cleaning and drying with internal channels, blind holes and details that have a complex geometry. These type of machines are basically used to wash and dry heavy components like valve bodies, transmission parts, cylinder blocks, aerospace parts, wind electric generator sub-assemblies, wheels etc.

- Complete SS304 Construction.

- High pressure alkaline spray wash & Flood wash in Single stage.

- Flood immersion wash with agitation.

- Injection flood wash

- Ultrasonic cleaning system

- Final alkaline spray wash

- Rinse ( Recirculate / Fresh )

- Hot air / compressed air

- Vacuum dry.

- Automatic Door open & close.

- Customized Basket.

- Wash tank & Rinse tank.

- High pressure vertical alkaline pressure wash pump.

- Working temperature of wash fluid 60 -70°C.

- Single tank / two tanks concept with insulation.

- High pressure Injection flood wash and Ultrasonic transducer.

- Special custom build basket to suit the component.

- Front loading with Loading & Unloading table.

- Fully enclosed front loading component cleaning machine.

- Automatic door open & close.

- PLC controlled process.

- HMI & Digital temperature controller.

- Two hand push button with safety screen sensor.

- Oil separator.

- Efficient Ultrasonic generator with ultrasonic cleaning transducer.

- Drain pump for quick cycle time.

- Automotive engine & transmission parts like cylinder head, crankshaft, camshaft, gears, housings etc.

- Automotive systems like injection, break and steering systems, turbo chargers etc.

- Aerospace components.

- Precision components like medical, optical etc.

- Mass machined components like fasteners, Hydraulic parts etc.,

- Parts with blind holes.