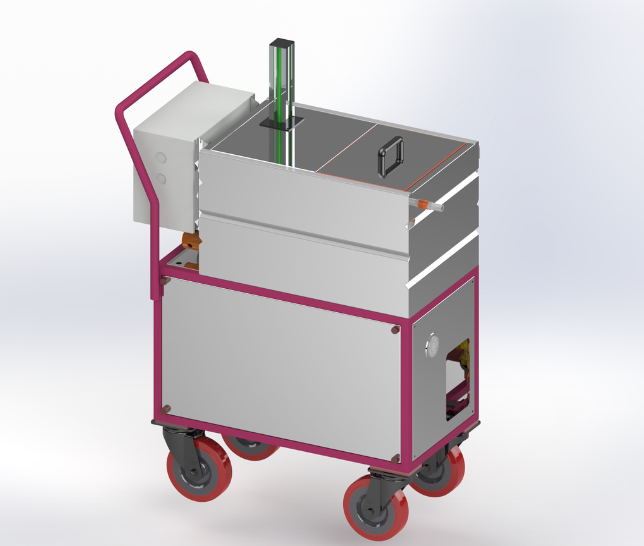

Conveyorised Component Cleaning Machine

Ultravelox offers the highest quality industrial Conveyorized Component Cleaning Machine for component cleaning application, these conveyor parts washers are able to wash, rinse and dry up to your most demanding high volume component cleaning applications.

The components enter on one side and exit at the other side of the machine. Multiple components are cleaned simultaneously leading to lower cycle time. The machine can be designed as a continuous moving or stop-and-go type machines depending on the application with process washing, Rinsing & Drying. In addition, all cleaning and rinsing solutions are recirculating filtered through chip strainer baskets and fine filtration to ensure a long bath life.

We offer several standard models of Conveyorized Component Washing Machines in different sized conveyor width to meet almost every Conveyor washer spray cleaning application. These Conveyor Spray Washer use environmentally safe aqueous cleaning solutions for component cleaning operations to remove chips, oils, coolants and buffing compound from machined parts, plastic parts and stampings.

Our Conveyorized Component Washing has design features that allow us to custom tailor the specifications to our customer’s requirements. Wash Rinse & dry chamber length, width, height, along with pump capacity and as well as single and multiple lanes can all be tailored to suit the customer’s application

- Multi stage washing possible – Different processes in separate Chambers

- High volume production.

- Lower cycle times

- Modular design – easily add rinse, dry sections

- Auto loading and unloading – customisation.

- Thru Feed Type Washing Machine, for aiding online assembly operations.

- Fits into “in line” manufacturing layout.

- High pressure sprays wash.

- Rinse stage: re-circulating and non-recirculating

- Heated and non-heated Air blow for drying.

- The efficiency of the conveyor parts washer is enhanced by its ability to transport parts through a series of stages, optimizing the use of cleaning agents, water, and energy.

- Type of Conveyor : Slat Conveyor, Honeycomb, Wire & Mesh, Roller chain with fixture Type, etc. – it is selected depending on the part geometry and the cleaning application

- Complete water contacting parts in SS 304.

- Conveyor width : 300mm to 1500mm.

- Load carrying capacity : Maximum 175 kg / part/ metre.

- Variable speed conveyor

- Fully insulated solution tanks

- Pump pressure 4 to16 Bar

- Low Water Shut-Off – Protect your heat elements from low water conditions

- Filtration Bag/ Cartridge, Compact band, Wedge wire type

- Loading and unloading of components outside the cleaning chamber

- User friendly for heavier components handling by hoist or crane

- Mist collector.

- Oil separator.

- Duplex Filtration system.

- Two tank Filtration.

- Paper band filtration.

- Magnetic separator.

- Safety Sensor.

- JIB Crane for Component loading & Unloading.

- Removal of oil and chips from machined components, castings and housings.

- Automotive engine and transmission rebuild and manufacturing cleaning

- Cleaning prior to powder coating, welding, deburring, brazing, blasting or other surface cleanliness critical post process applications.

- Industrial parts washing of castings, stamped parts, machined parts, and other parts with true oils or water soluble coolants.

- HPDC Components cleaning machine.